- Gas Generator

- Diesel Generator

- Gas Power Plant

- Spare Parts

- Natural Gas Generator

- Biogas Generator

- Biomass Generator Set

- Diesel Generator Set

- Natural Gas Power Plant

- Biogas Power Plant

- Diesel Power Plant

- Engine Spare Parts

- Gas Engine Generator

- Diesel Engine Generator

- Engine Spare Part

- Captive Power Plant

Custom Service Upgrade Power Coating Prouction Line Plant

Basic Info

| Model NO. | HANNA-04-92 |

| Method Type | Manual |

| Condition | New |

| Design | Compact and Ecomonical |

| Material | Steel |

| Powder Coating Booth | PP/PVC |

| Reciprocator | Design Matched |

| Power Recovery Unite | Filter Type/Cyclone |

| Powder Recovery Rate | 98% |

| Powder Recovery Time | 10-15 Mins |

| Curing Oven | Natural Gas/Liquefied Gas/Electricity/Diesel |

| Oven Temperature | Consistent and Stable |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Wooden |

| Specification | customized |

| Trademark | HANNA |

| Origin | China |

| HS Code | 8424300000 |

| Production Capacity | 200 Set Per Year |

Product Description

Powder Coating System-Customized, Semi-Automatic/Manual Powder Coating System

1. Pre-treatment system (Dipping tank/spraying/shotblasting)2. Drying oven for chemical pretreatment3. Powder coating4. Powder curing ovenPretreatment SystemSpray Pretreatment

Spraying Pretreatment Stainless Steel Chemical Tank With Pump Spraying Nozzle Stainless Steel Spraying Tunnel

Dip Tank Pretreatment

Powder Coating Booth

Quick Coloar Change Powder Coating Booth With Cyclone Quick Assemble Filter Recovery Powder Coating Booth

* Powder recovery rate as high as 99.2% * Powder recovery rate: 98%* Color change time: 10-15 minutes * Color change time: 15 minutes* Suitable for multiple color more than 3 * Reduce production stagnation time and increase productivity* No dust spillover, reduce powder waste * Advantages: Economical* Save labor time * Disadvantages: Not suitable for multiple color change* Improve the quality of spraying

Drying&Curing Ovens

Bridge Type Oven Tunnel Type Oven Box Type Oven

Hanna Oven Advantages:

1.The air curtain are at both ends of the oven, the hot air in the oven won't dissipate to outside, saving the fuel .2. Curing oven insulation board are all plug-in board, seamless docking, thermal bridge transmission technology.3. Hot air circulation air supply and return reach a balance, reasonable layout, uniform oven temperature. After testing, the temperature difference in the oven is less than ± 3 ºC.150mm thickness insulation layer Inside view for our curing oven Oven temperature tracker record

Project Cases

At Hanna, we do more than just build equipment and powder coaing lines.Our staff includes coating system designers, powder and chemistry experts, control systems engineers, technical support personnel, installation technicians and experienced trainers.We build equipments with Hanna and Zhanyao brand, but also we work directly with OEM clients to provide "private label" powder coating equipment manufactured to their specifications.We've built thousands of optimal customized lines and systems for powder coating operations across China and around the world. Hanna's list of satisfied clients includes successful small manufacturers, government organizations, and global corporations.You won't find a better combination of quality, value and support anywhere in this industry. Each piece of equipment is built to meet your specific needs. To make sure you get the best results, our factory-authorized technician team will help you work through the details and get the results you need. We will design, build, deliver your automated system and if more services needed, we can help to install, fine-tune and train your operators to get premium results.

Company Profile

Since 1990, from simple manual spraying to automatic powder spraying system. We can provide you with innovative, rational and economical solutions. We can support you with advanced technologies.Delivering the best powder coating equipments and turn-key solutions. We've built thousands of optimal customized lines and systems for powder coating operations across China and around the world. Our continuous research on the field as well as our constantly developing techniques and innovative nature of our engineering dpt. enable our customers to catch up to the latest developments by modernizing their equipment partly or wholly, so as to improve performance, increase profits and maintain their competitiveness in the world of trade. Our company has passed ISO9001 certification,CE certification, and has obtained more than 70 patents.

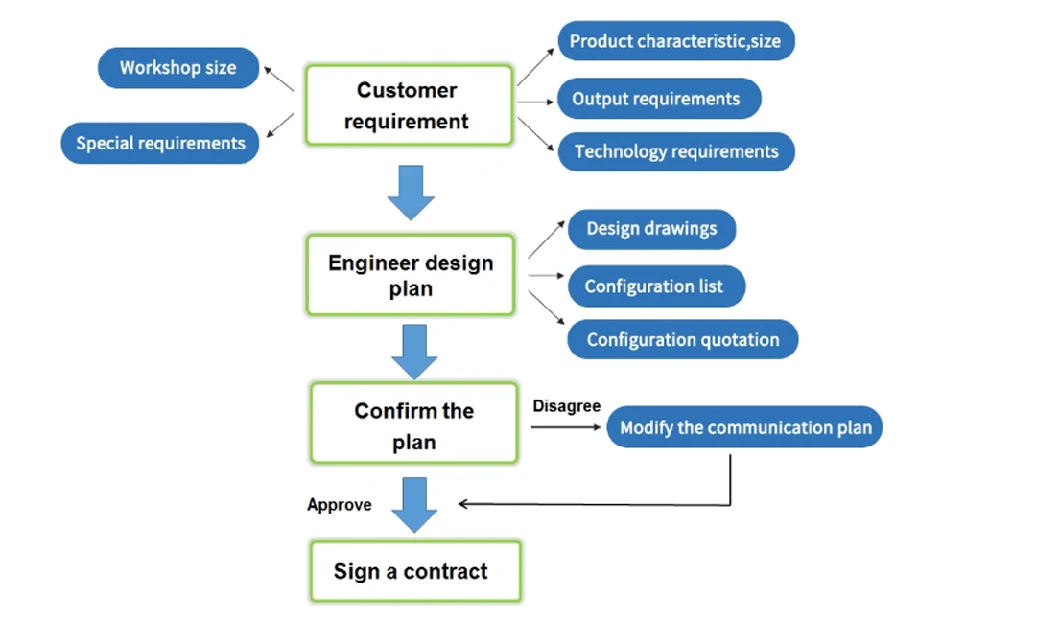

Ordering Process

FAQ

Are you a trader or a factory?

We are manufacturer and exporter. Our own factory was found in 1990,Our export office was established in 2014.

What should I provide if interested in your powder coating equipment ?A. The material/size(max)/weight(max)of your workpiece.B. How many of your daily output(one day=8hours,one month=30days)?C. What heating power do you prefer: electric,gas, diesel or coal?D. The size of your factory(length, width and height)?

How to ensure the quality of the equipment?A. We have hundreds of patents and passed the IS9001:2015 quality management system certification.B. The Technical Review Committee,reasonably determines and divides the stages of design, production, installation andcommissioning, and formulates detailed progress plans for each stage, Strengthen the quality assurance system and quality protection measures of equipment manufacturing department.C. We manning quality inspectors specially to control the processing quality of product strictly.

How to install equipment after purchasing your equipment?A. We will provide installation information and installation videosB. Our engineers will guide the installation and run the equipment.C. After the debugging, will provide complete training and track customer device usage.

How is your company's after-sales service done?A. Provide the list of consumables to assist customers in establishing acomprehensive equipment maintenance system.B. After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.C. If customer has a device failure in the process of using the device,our company will operate the device remotely through the computer network through the authorization given by the customer, and eliminate all equipment failure problems. D. Any problems with the equipment, our company guarantees to give solutions within 12 hours.

![Jinan Diesel Engines A12V190zl-2 <a href="/cdn-cgi/l/email-protection" class="__cf_email__" data-cfemail="320a03025945720302020240425f">[email protected]</a>](/uploads/s/e09dbf4ce1a44228b0287f93afd89624.webp)